Terra cotta, or “burnt clay,” is a hard baked, high grade of weathered or aged clay. It is similar to brick but the clay is of higher quality and fired at higher temperatures. This article focuses on exterior architectural terra cotta as distinguished from statuary, pottery , and terra cotta blocks used as inner wythes of wall or fill material.

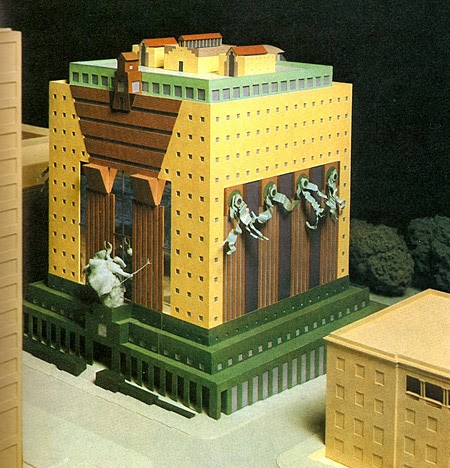

The 1893 Columbian Exposition in Chicago demonstrated the versatility and ornamental qualities of terra cotta. It highlighted the great variance in color and shapes possible with terra cotta and began the demand in the United States for terra cotta that lasted through the late 1930s. Terra cotta is prized for its light weight, longevity, aesthetic qualities, and unit construction. At the peak of production, almost every urban area in America was producing architectural terra cotta in some variation. Today, most replacement units are produced by either Gladding McBean or Boston Valley Terra Cotta.

Specific forming techniques including hand press, machine press, slip casting, and extrusion are used depending on the shape and style of unit required. In the analysis of terra cotta failure the forming techniques are less critical than the strength characteristics of the fired clay, the integrity of the exterior surfaces, and structural support systems.

Exterior ornamental terra cotta was marketed as a light weight water proof cladding. And if proper construction techniques were employed, and the system was maintained, and the local climates were mild, terra cotta performed as sold. However, terra cotta adorns buildings in severe weather climates, and is installed with structural materials affected by environmental conditions, and located on façade elements inaccessible for routine maintenance.

The mortar joints are the material most susceptible to failure. Joints often exist on all three axis with some units of terra cotta designed for flat horizontal surfaces. Over time and exposure, the mortar fails providing a means for water intrusion. Sever cycling of weather in simultaneous freeze/thaw conditions can cause the terra cotta clay to expand and contract, accelerating the crazing or cracking of the protective glaze. Extensive crazing can lead to glaze spalling and allow for further water intrusion.

Once water enters the system there is no weep path allowing for water egress. Construction means and methods, as well as the cellular unit design, trap water and contribute to the potential corrosion of steel lintels, wire ties, steel structural support members, and other miscellaneous metals. Rapid freezing and thawing cycles, in addition to steel corrosion, can crack terra cotta units. If the units remain unrepaired, further water intrusion and/or absorption will occur.

The repair of terra cotta will depend both on the cause and manifestation of the defect. Typical defects include crazing of the glazed finish, shallow surface spalls, deep spalls affecting the bisque, cracked units, inadequate support and / or anchorage, corrosion induced stress fractures, impact damage, mortar degradation, lack of maintenance, and inadequate repairs.

Proper terra cotta repair methods are linked to the cause of defect. Repair techniques are often performed on-site by skilled tradesmen. When damage to the terra cotta unit is severe, full replacement may be required. Defects due to inadequate support or a result of corrosion to supporting steel members is likely to require more invasive repair strategies including removal and replacement of several courses of interlocked terra cotta units.

When replacement units are not required and the scope is limited to on-site repair, labor costs exceed material costs. Since many historic terra cotta units were specialty designed and installed for the structure, a premium price is paid for replacement. New exterior decorative terra cotta is available only from the sources referenced and with small quantity orders, the first unit is approximately $5,000 with much of the costs attributed to making the form and determining the finish color and texture. Subsequent costs per unit will decrease with the range of decrease dependent upon quantities required.

When replacement units are not required and the scope is limited to on-site repair, labor costs exceed material costs. Since many historic terra cotta units were specialty designed and installed for the structure, a premium price is paid for replacement. New exterior decorative terra cotta is available only from the sources referenced and with small quantity orders, the first unit is approximately $5,000 with much of the costs attributed to making the form and determining the finish color and texture. Subsequent costs per unit will decrease with the range of decrease dependent upon quantities required.

The most important component of terra cotta repair is an understanding the cause of deterioration and the proper repair specifications. Both are derived after a full condition assessment and evaluation of the existing conditions.

Written by Peter Meijer AIA, NCARB, Principal

——————–

Sources

• Last of the Handmade Buildings, Virginia Guest Ferriday, Mark Publishing Co., Portland, OR 1984

• National Park Service, Preservation Brief No7, Preservation of Glazed Terra Cotta

• APT Pacific NW Chapter 2005 workshop

• Terra Cotta, Standard Construction, Revised Ed., National Terra Cotta Society, 1927

Are masonry sealers necessary on historic multi-wythe exterior walls? In general, likely not. Traditional exterior mass unit masonry walls, 3 to 4 wythes thick, leak. But rarely does the amount of water intrusion cause damage to the masonry, the masonry ties, or the interior finishes. Why wouldn’t a sealer be effective for these older walls?

Are masonry sealers necessary on historic multi-wythe exterior walls? In general, likely not. Traditional exterior mass unit masonry walls, 3 to 4 wythes thick, leak. But rarely does the amount of water intrusion cause damage to the masonry, the masonry ties, or the interior finishes. Why wouldn’t a sealer be effective for these older walls?  The porosity and absorption rates of older masonry are often exaggerated because of the brick appearance. Many older masonry units show the results of imperfect firing techniques. It is not unusual to see older masonry with vertical and horizontal cracks due to low firing temperatures or impurities in the original clay mix. The surface cracks may lead to higher rates of absorption around the crack but rarely increase the overall absorption or alter the overall characteristics of the masonry. Masonry sealers will not bridge these firing cracks.

The porosity and absorption rates of older masonry are often exaggerated because of the brick appearance. Many older masonry units show the results of imperfect firing techniques. It is not unusual to see older masonry with vertical and horizontal cracks due to low firing temperatures or impurities in the original clay mix. The surface cracks may lead to higher rates of absorption around the crack but rarely increase the overall absorption or alter the overall characteristics of the masonry. Masonry sealers will not bridge these firing cracks.

To control water intrusion and to increase performance of a masonry wall, it is much more effective to maintain mortar joints through re-pointing process, assure that mortar joints have no voids, replace brick with spalled faces, replace brick that are cracked the full depth, and repair bond line failures. The use of masonry sealers should be based on known research and field tested success and not chosen as a means to remedy poor construction methods.

To control water intrusion and to increase performance of a masonry wall, it is much more effective to maintain mortar joints through re-pointing process, assure that mortar joints have no voids, replace brick with spalled faces, replace brick that are cracked the full depth, and repair bond line failures. The use of masonry sealers should be based on known research and field tested success and not chosen as a means to remedy poor construction methods.

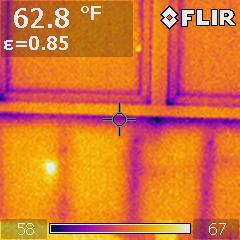

When severe deterioration of masonry walls is not a prevalent condition, what other non-visual processes are employed to determine the cause of deterioration? Two common techniques, well known to historic preservation professionals, are non-destructive testing (NDT) and material testing in the laboratory. NDE methods include RILEM tube water absorption tests, metal detector scanning, video scopes, infra-red photography, ultra sound testing, ground penetrating radar, and in some cases, x-ray diffraction. Common laboratory testing include petrographic examination, electron microscopy, and Fourier Transform Infrared (FTIR) methods.

When severe deterioration of masonry walls is not a prevalent condition, what other non-visual processes are employed to determine the cause of deterioration? Two common techniques, well known to historic preservation professionals, are non-destructive testing (NDT) and material testing in the laboratory. NDE methods include RILEM tube water absorption tests, metal detector scanning, video scopes, infra-red photography, ultra sound testing, ground penetrating radar, and in some cases, x-ray diffraction. Common laboratory testing include petrographic examination, electron microscopy, and Fourier Transform Infrared (FTIR) methods.  FTIR, when combined with the diagnostic RILEM tube field test, in particular is an effective evaluation to determine if masonry sealers have been applied to a wall surface impeding the capillary evaporation of trapped water. RILEM tests also provide an observation of a masonry wall’s initial rate of absorption under wind driven rain circumstances. Petrographic analysis of both masonry and mortars determines the material composition and will identify harmful natural elements and harmful additive elements like salts.

FTIR, when combined with the diagnostic RILEM tube field test, in particular is an effective evaluation to determine if masonry sealers have been applied to a wall surface impeding the capillary evaporation of trapped water. RILEM tests also provide an observation of a masonry wall’s initial rate of absorption under wind driven rain circumstances. Petrographic analysis of both masonry and mortars determines the material composition and will identify harmful natural elements and harmful additive elements like salts. A common misconception in the northwest is that surface spalls are a result of freeze thaw cycles. Freeze thaw susceptibility can only be determined through laboratory testing. Visual observations are insufficient to conclude masonry spalls resulted from freeze thaw forces. Since freeze thaw tests are graded either pass or fail, further tests methods are typically required for additional diagnostic evaluation. More likely sources of surface spalls are hard Portland cement mortars which exceed the strength of the masonry, salts introduced into the masonry through incorrect material selection, or surface sealers impeding the evaporation of water and thus creating a saturated sub surface layer which will freeze. (It is important to distinguish that the masonry unit may not be susceptible to freeze thaw but rather the sealer creates a dam like effect inducing a layer of water subject to freezing)

A common misconception in the northwest is that surface spalls are a result of freeze thaw cycles. Freeze thaw susceptibility can only be determined through laboratory testing. Visual observations are insufficient to conclude masonry spalls resulted from freeze thaw forces. Since freeze thaw tests are graded either pass or fail, further tests methods are typically required for additional diagnostic evaluation. More likely sources of surface spalls are hard Portland cement mortars which exceed the strength of the masonry, salts introduced into the masonry through incorrect material selection, or surface sealers impeding the evaporation of water and thus creating a saturated sub surface layer which will freeze. (It is important to distinguish that the masonry unit may not be susceptible to freeze thaw but rather the sealer creates a dam like effect inducing a layer of water subject to freezing) By combining visual observations with NDE and lab testing, most surface masonry deterioration can be determined and thereby implement proper repair, maintenance, and protection methods.

By combining visual observations with NDE and lab testing, most surface masonry deterioration can be determined and thereby implement proper repair, maintenance, and protection methods. Our first choice, and ethical preference, is to retain historic wood windows. Repaired and maintained wood windows constructed of old growth lumber will outlast any modern alternative. We advocate strongly for a process and philosophy that seriously evaluates retaining original material. The best approach compares long-term costs, embodied energy, and cultural importance relative to the same criteria for new replacement material.

Our first choice, and ethical preference, is to retain historic wood windows. Repaired and maintained wood windows constructed of old growth lumber will outlast any modern alternative. We advocate strongly for a process and philosophy that seriously evaluates retaining original material. The best approach compares long-term costs, embodied energy, and cultural importance relative to the same criteria for new replacement material. Most existing, older properties have had more than one owner. Research into original design documents, major rehabilitation projects, building permit requests, and other documents provide insight into processes that might have replaced original material. The removal and replacement of non-original material is justifiable and acceptable rationale.

Most existing, older properties have had more than one owner. Research into original design documents, major rehabilitation projects, building permit requests, and other documents provide insight into processes that might have replaced original material. The removal and replacement of non-original material is justifiable and acceptable rationale.  After a thorough evaluation and understanding of the existing wood windows, the next decision is to choose a replacement product. In-kind replacement,(i.e. wood window for wood window; true divided lites for true divided lites, matching pane divisions, etc.) is preferred. When the replacement window is virtually identical to the historic window, it is hard to say no. Absent exact replacement, the visual qualities exhibited by the cross section profiles, the sash height and width, and the proportion of wood to glazing, are the most important attributes to match. Appearance from the exterior will trump appearance from the interior during a historic review approval process.

After a thorough evaluation and understanding of the existing wood windows, the next decision is to choose a replacement product. In-kind replacement,(i.e. wood window for wood window; true divided lites for true divided lites, matching pane divisions, etc.) is preferred. When the replacement window is virtually identical to the historic window, it is hard to say no. Absent exact replacement, the visual qualities exhibited by the cross section profiles, the sash height and width, and the proportion of wood to glazing, are the most important attributes to match. Appearance from the exterior will trump appearance from the interior during a historic review approval process. When an opportunity to retain original fabric/windows is available, the opportunity should be incorporated into the work. Even retaining as little as 20% of historic fabric will increase the likelihood of approval for replacement of the remaining components. The retention of historic fabric also allows successive generations to better understand the history and changes of an existing property.

When an opportunity to retain original fabric/windows is available, the opportunity should be incorporated into the work. Even retaining as little as 20% of historic fabric will increase the likelihood of approval for replacement of the remaining components. The retention of historic fabric also allows successive generations to better understand the history and changes of an existing property.

Space programming respected the historic floor plan and scale of the original structure and recreated Yeon’s original design intent of integrating indoor space with outdoor space. Extraneous equipment and unsympathetic additions were removed from both the interior and exterior. Interior design elements, furniture, and fixtures maintain the open gallery spacial quality while integrating new furniture and fixtures meeting the needs of the tenant. Major preservation focused on the exterior restoring original paint colors through serration studies, restoring building signage in original type style and design, preserving original wood windows, when present, and restoring the intimate courtyard with a restored operating water feature.

Space programming respected the historic floor plan and scale of the original structure and recreated Yeon’s original design intent of integrating indoor space with outdoor space. Extraneous equipment and unsympathetic additions were removed from both the interior and exterior. Interior design elements, furniture, and fixtures maintain the open gallery spacial quality while integrating new furniture and fixtures meeting the needs of the tenant. Major preservation focused on the exterior restoring original paint colors through serration studies, restoring building signage in original type style and design, preserving original wood windows, when present, and restoring the intimate courtyard with a restored operating water feature. Moore, Lyndon, Turnbull & Whitaker’s 1965 Pavilion at Lawrence Halprin’s Lovejoy Fountain is a whimsical all wood structure with a copper shingle roof. Although a small structure, the pavilion represents a major mid-transitional work for Charles Moore as his design style moved from mid-century modern to Post-modern design. In keeping with the naturalistic design aesthetic established by Halprin, northwest wood species comprise the major structural system including the roof trusses, vertical post supports, and vertical cribs built from 2 x 4 members laid on their side and stacked.

Moore, Lyndon, Turnbull & Whitaker’s 1965 Pavilion at Lawrence Halprin’s Lovejoy Fountain is a whimsical all wood structure with a copper shingle roof. Although a small structure, the pavilion represents a major mid-transitional work for Charles Moore as his design style moved from mid-century modern to Post-modern design. In keeping with the naturalistic design aesthetic established by Halprin, northwest wood species comprise the major structural system including the roof trusses, vertical post supports, and vertical cribs built from 2 x 4 members laid on their side and stacked. The restoration approach is intended to correct the structural deficiencies and replace the failed members with no changes to the historic appearance of the structure. The crib design allows for insertion of new steel elements, invisible from the exterior, capable of providing additional support for vertical loads. The difficulty arises because standard wood products available today have different visible and strength attributes from standard components available in 1965. Sourcing appropriate lumber is dependent upon clear and quantifiable specification, high quality inspection, and visual qualities. There are no structural standards for reclaimed or recycled lumber compounding the incorporation of “old growth” lumber as part of a new structural system. When original source material is no longer available, best practices for narrowing the selection of new materials will of necessity be combined with subjective visual qualities and a best-guess scenario as to how the new material will age in place similarly to the historic material. There are no single solutions so experience is key.

The restoration approach is intended to correct the structural deficiencies and replace the failed members with no changes to the historic appearance of the structure. The crib design allows for insertion of new steel elements, invisible from the exterior, capable of providing additional support for vertical loads. The difficulty arises because standard wood products available today have different visible and strength attributes from standard components available in 1965. Sourcing appropriate lumber is dependent upon clear and quantifiable specification, high quality inspection, and visual qualities. There are no structural standards for reclaimed or recycled lumber compounding the incorporation of “old growth” lumber as part of a new structural system. When original source material is no longer available, best practices for narrowing the selection of new materials will of necessity be combined with subjective visual qualities and a best-guess scenario as to how the new material will age in place similarly to the historic material. There are no single solutions so experience is key. Case Study 3

Case Study 3

When replacement units are not required and the scope is limited to on-site repair, labor costs exceed material costs. Since many historic terra cotta units were specialty designed and installed for the structure, a premium price is paid for replacement. New exterior decorative terra cotta is available only from the sources referenced and with small quantity orders, the first unit is approximately $5,000 with much of the costs attributed to making the form and determining the finish color and texture. Subsequent costs per unit will decrease with the range of decrease dependent upon quantities required.

When replacement units are not required and the scope is limited to on-site repair, labor costs exceed material costs. Since many historic terra cotta units were specialty designed and installed for the structure, a premium price is paid for replacement. New exterior decorative terra cotta is available only from the sources referenced and with small quantity orders, the first unit is approximately $5,000 with much of the costs attributed to making the form and determining the finish color and texture. Subsequent costs per unit will decrease with the range of decrease dependent upon quantities required.

Infrared camera analysis adds another diagnostic layer of evaluation data. Temperature differentials between wet and dry surfaces can collaborate other visual observations. However, a number of varying conditions, not just water, can cause temperature differences between materials or even temperature differences within the same material. For instance, an exterior stucco wall installed over steel studs may have extreme temperature changes as a result of heat conductance through the steel studs with no related water intrusion.

Infrared camera analysis adds another diagnostic layer of evaluation data. Temperature differentials between wet and dry surfaces can collaborate other visual observations. However, a number of varying conditions, not just water, can cause temperature differences between materials or even temperature differences within the same material. For instance, an exterior stucco wall installed over steel studs may have extreme temperature changes as a result of heat conductance through the steel studs with no related water intrusion.