Size

274,489sf

Cost

$158 million total (assessment part of larger modernization project)

Date

2015 – 2017

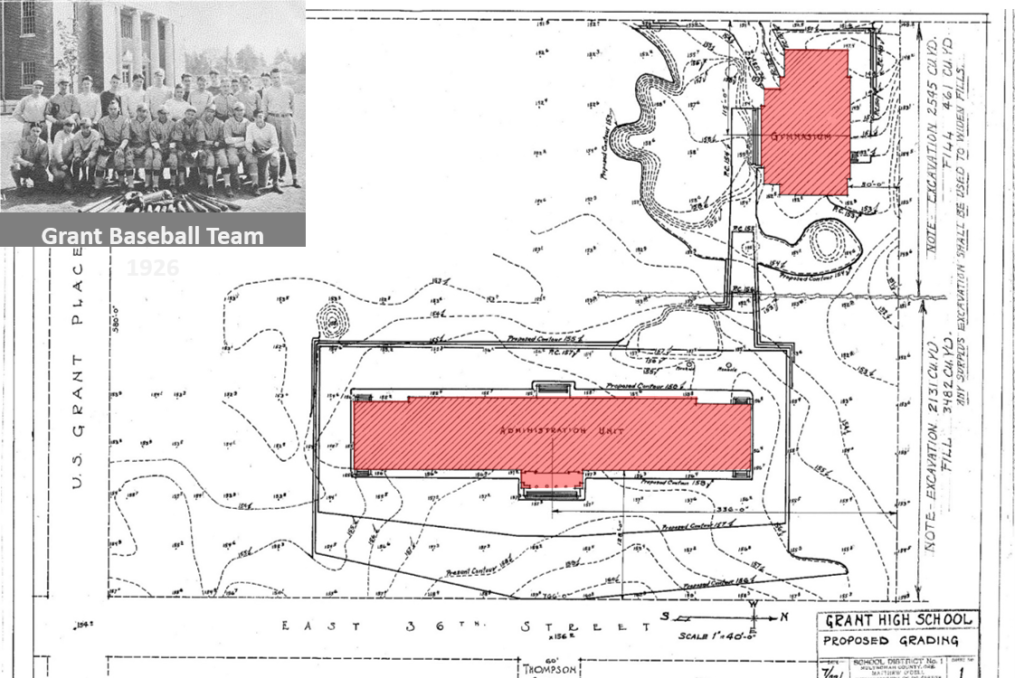

When it was completed, Grant High School was typical of the high schools constructed by Portland Public Schools in the pre-World War II era. In addition to being an extensible school, including educational buildings constructed between 1923 and 1970, the school was also reflective of fire-proof construction through its use of a reinforced concrete structure with brick in-fill. (Portland Public Schools, Historic Building Assessment, Entrix, October 2009)

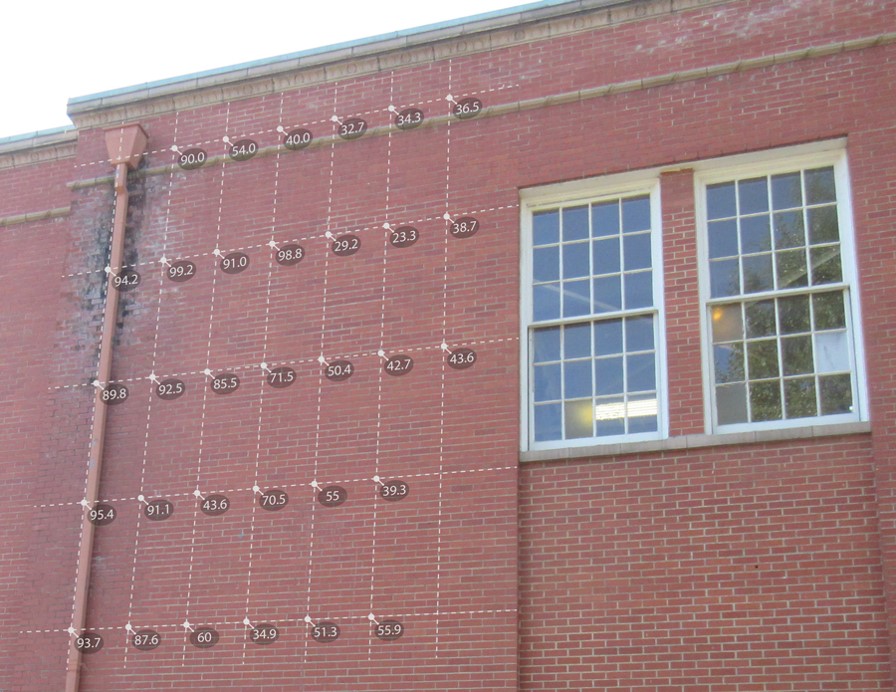

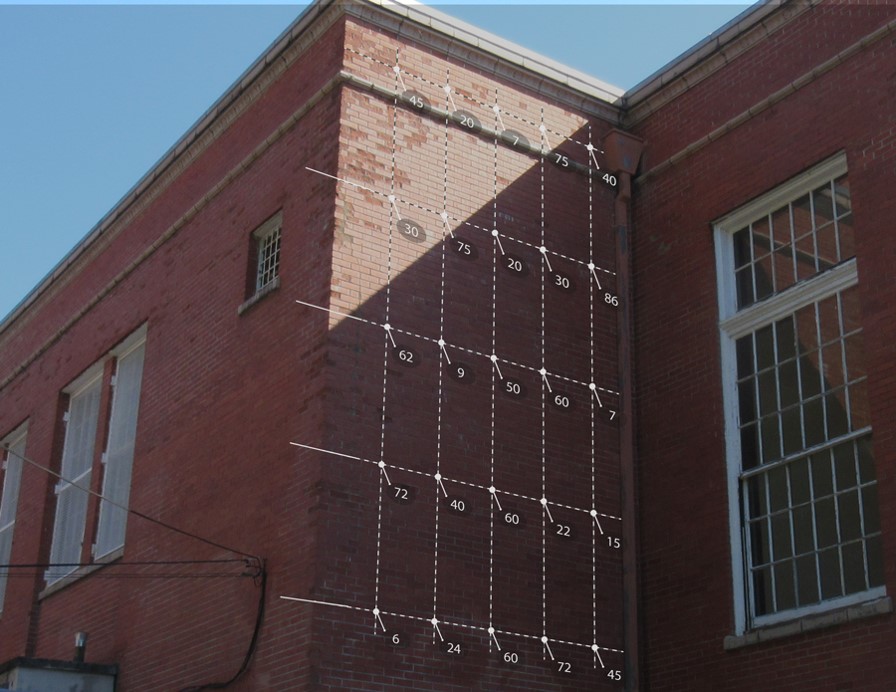

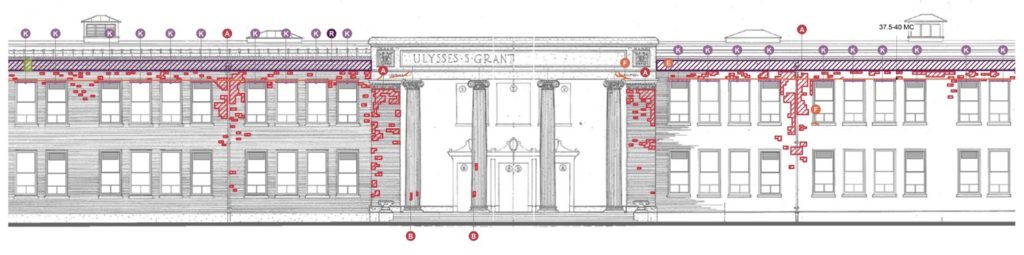

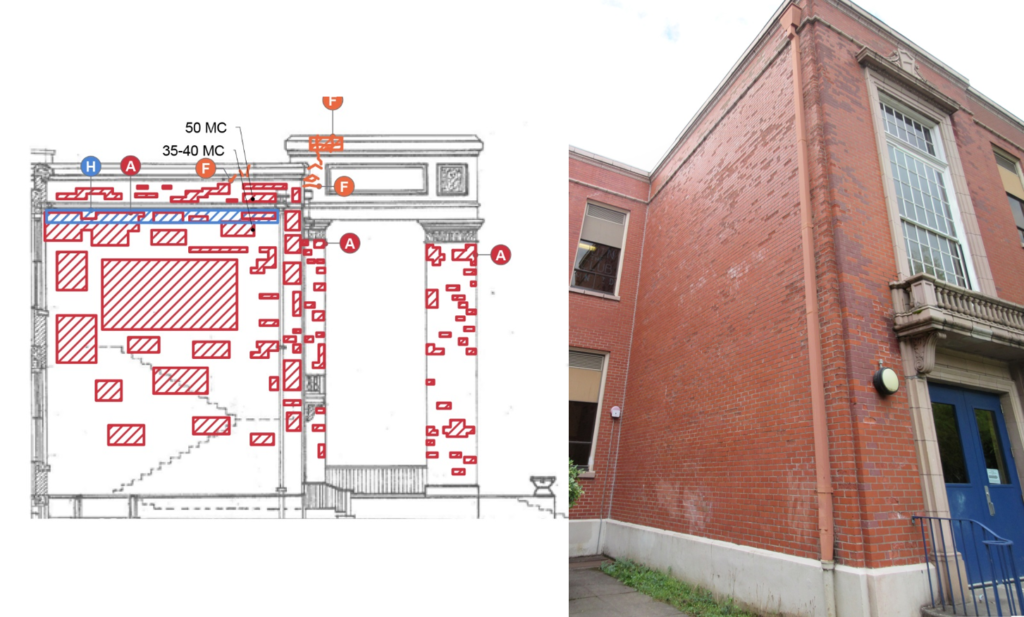

Over the last fifteen years, Portland Public Schools (PPS) noted an accelerated degree of masonry face spalling on the original 1923 main building and 1923 Old Gym particularly when adjacent to concentrated sources of surface water. Other areas of spalling were not as obvious including protected wall surfaces. The masonry spalling was not occurring on later additions including the north wing (circa 1925), south wing (circa 1927), and auditorium building (circa 1927). Upon closer visual examination, it was observed that individual units were failing in isolated protected areas of the wall surface. Failures in such areas could not be accounted for under direct correlation of heavy water intrusion and typical failure mechanisms.

The failure of the brick was potentially due to a number of separate or cumulative conditions

including:

1. Excessive water uptake by the brick

2. Sub-fluorescence expansion of salts in the masonry

3. Freeze thaw

4. Low quality of the original 1923 brick, and/or

5. The application of surface sealers preventing water migrating to the exterior surface

As a result of the hypothesis and field observations, it was prudent to conduct a series of lab tests to the brick, mortar, and patch materials to assist in the determination of 1) the quality of the brick; 2) the physical composition of the brick; 3) the quantity of naturally occurring compounds in the masonry and mortar, particularly salts in the masonry; and 4) the quality of the mortar.

The findings would help narrow the potential cause of the spalling and lead to a more focused repair and maintenance process. Bricks were removed for testing of Initial Rate of Absorption (IRA), a test for susceptibility to water saturation, freeze thaw testing, and petrographic analysis, a way to determine the inherent properties of the clay and manufacturing process. Both pointing and bedding mortar samples, as well as, the previous patching material were removed and also tested. To rule out damage caused by maintenance procedures, faces of the brick material were sent to determine if sealants were used on the brick and, if present, determine the sealant chemical makeup. The presence of a surface coating may lead to retention of water within the brick and thus prevent natural capillary flow, natural drying, and water evaporation.

Following modified ASTM standards, a 24-hr immersion and 5-hr boil absorption test on the brick were performed. The brick have a very low percent of total absorption at 9.5% for the 5-hr boil and 7.5% for the 24-hr test. The maximum saturation coefficient is 0.79 which is 0.01 over the maximum requirements for Severe Weathering bricks recommended for Portland climate (ASTM C216-07a Table 1). The Initial Rate of Absorption (IRA) is 5.7g/min/30in2 which equates to a very low suction brick or brick with low initial rates of absorption. The freeze thaw durability tests resulted in passing performance. All of these tests refuted the hypothesis that freezing temperatures were the cause of masonry spalling.

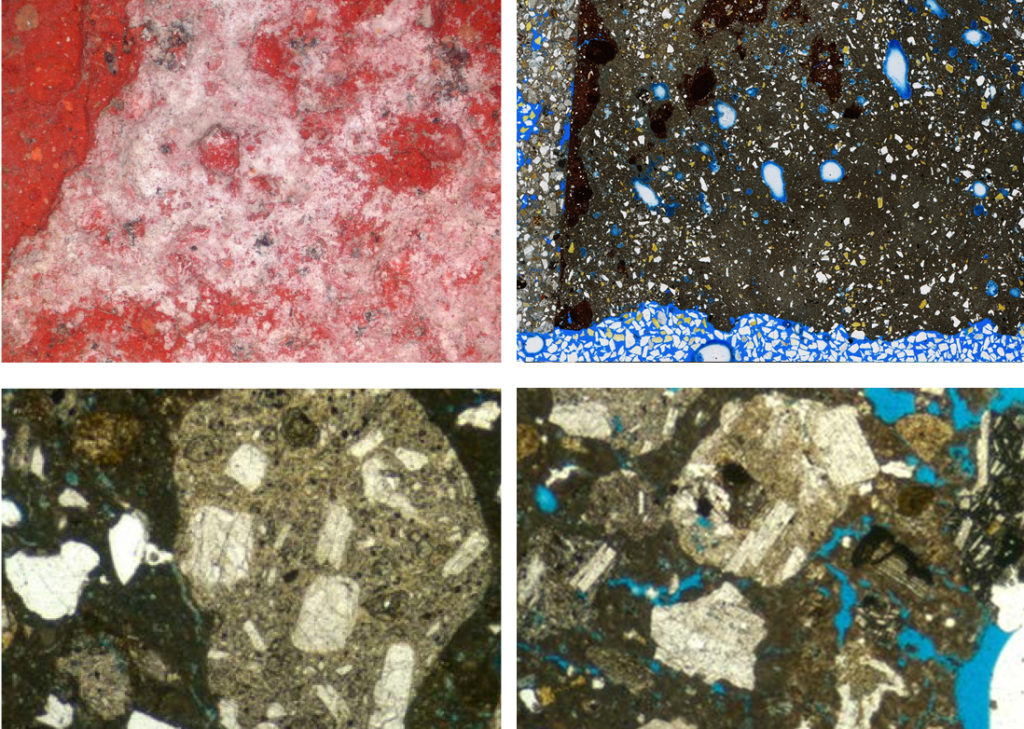

A brick material analysis was performed in general conformance with ASTM C856, ASTM C1324 (masonry mortar) and included petrographic analysis, chemical analyses, x-ray diffraction and thermogravimetric analysis. Samples were analyzed under a polarized light microscope for information such as materials ratio and presence or absence of different deterioration mechanisms. These tests were used to assess the overall quality of material, presence of inherent salts, excessive retempering, cracking, ettringite formation, and potential alkali‐silica reactivity.

Unusual Findings and Relevant Results

The Petrographic Characterization resulted in the most unusual findings and the most relevant results related to the observed failures. The polarized light microscope indicated carbonate based salt crystals seeping into the masonry from the mortar. No sulfate based salts, typically associated with the clays used for making brick, were present. Furthermore the inherent properties of the brick showed very small rounded voids and interconnected planer voids. Planner voids result from poor compaction during the raw clay extrusion process prior to firing.

Performance of brick in the field is a result of both material properties and resistance to micro-climates within the brick’s capillary void structure which cannot be repeated in the lab. Studies have shown a connection between small voids in the material property and susceptibility to longer water retention near the surface. With natural absorption properties, the brick is taking in a small quantity of water in very small pores. 24-hour immersion results are very low (7.5%). Publication of more in-depth studies correlates maximum saturation values for brick with low 24-hour immersion values. The effect of low immersion values and small quantities of absorbed water may increase the susceptibility in brick with small pore structure to freeze thaw failure.

The presence of salt migration out of the mortar and into the brick, plus small pore structure and low immersion values, combining with a cleavage plane resulting from manufacturing are contributing to the Grant High School brick spalls. Brick with smaller pores are less capable of absorbing the expansive forces of freezing water and drying salts. Interlaced pores creating linear plains parallel with the face of the brick create stress failure points resulting in surface spalling. Since the characteristics of the brick resulted from the firing and manufacturing process, the brick will remain susceptible to the failure mechanisms.

In summary, the primary findings were:

1. Failure mechanism inherent in manufacturing process. Likely due to poor bonding of clay during extrusion.

2. Low IRA is good and due to small diameter capillaries within brick. However, there is a correlation between small diameter capillary and susceptibility to expansion failures.

3. Salts in cement based mortars are leaching into the masonry over long periods of time. Upon drying, expansion of the salts within capillaries causing excessive force.

4. Some micro-climate freeze thaw may be occurring.

The best corrective action is to minimize the amount of surface water and proper mortar joints and mortar composition. Additional spalls are likely to occur in the future due to the accumulation of expansive forces over a long period of time. Replacement of the spalled bricks is recommended over further patching. Leaving spalled brick in place will continue to worsen the condition over time and affect adjacent brick.

Recommendations

PMA worked with Portland Public Schools to identify methods to slow the failure mechanism and prevent acceleration the brick spalling. Those recommendations included:

1. Control external water – repair all downspouts, gutters, and roof flashing systems for water tightness.

2. 100% repointing with lime based mortar – replacement of the cement based mortars will reduce the salt migration and reduce the expansive forces of salt dehydration.

3. Replace all failed brick units – reduce the spreading of failure.

4. Provide no masonry sealers – any trapped latent moisture needs to dry to the exterior. And masonry sealers have high maintenance requirements.

5. Provide further invasive openings at structural steel locations to verify that corrosion process has not reached the embedded structural steel.