It has been widely accepted by the larger building industry that the greenest building is the one that already exists, first posited by AIA president Carl Elefante in 2007. While this statement is frequently quoted, its specific implication has not enjoyed widespread application by the AEC industry—that improvements to existing buildings are quantifiably better at limiting greenhouse gas emissions than the construction of entirely new buildings. PMA’s case study goes beyond the assumption of “greenest building” by comparing data from an existing building rehabilitation project to the alternative, new construction. It also supports Elefante’s notion that preservation can be sustainable. This blog is a snapshot of PMA’s findings which are informed by existing data on embodied and operational carbon. It is important, in the industry’s push to reach net-zero by 2050, to understand how to measure a building’s carbon footprint—that begins with understanding the difference between embodied carbon and operational carbon. (Architecture2030, “Why the Built Environment” [Why The Building Sector? – Architecture 2030])

A building’s carbon footprint is found by calculating its embodied carbon and operational emissions. Embodied carbon is a measurement of the carbon dioxide and emissions produced during the construction of a building. It includes the sourcing of raw materials, the creation or production of new materials, the transportation of new materials and the emissions expelled during the construction process. Operational emissions are energy consumption tied to the building’s ongoing performance and use (World Economic Forum, “This is the next hurdle in the construction industry’s race to net-zero,” September 20, 2022, What Is Embodied Carbon? Overview and Examples). In the AEC industry, net-zero, also known as carbon neutrality, refers to a building’s carbon footprint (its embodied carbon and emission production or energy consumption) being equal to or less than that generated on site (Steven Winter Associates, Inc., “Net Zero Energy Buildings,” Whole Building Design Guide, August 2, 2016.).

Every building has both operational emissions, tied to ongoing use, and embodied carbon, created during the building’s construction. Combining a building’s operational emissions with its embodied carbon gives us that building’s carbon footprint. The larger a building’s carbon footprint is, the more detrimental its impact on the global warming potential. While a building’s operational emissions can increase or decrease depending on its continued performance and the efficiency of its mechanical systems, a building’s embodied carbon will remain tied to the building during its usable lifetime and then, after demolition, will remain tied to the wasted materials transported and consequently stored in a landfill.

There are ongoing efforts to measure and limit the AEC industry’s overall carbon footprint. The current goal of the industry is to achieve net-zero by 2040 to meet standards set by the Paris Climate Accords. Net-zero for the industry would be achieved when carbon emissions are zero or are 100% off-set by green energy produced.

One solution is the reuse of existing buildings. Existing building’s embodied carbon is significantly lower than new buildings because they generally do not require as many raw new materials as new buildings.. Rehabilitating existing buildings for the needs of today is one way that today’s designers are limiting the AEC industry’s carbon footprint.

PMA focuses exclusively on existing and historic buildings and has been exploring the feasibility of implementing net-zero in future renovation projects. The current goal is to measure the carbon footprint of finished or ongoing projects in the design phase to quantify the environmental impact of existing renovation compared to new construction. Former PMA intern, Caitlin Beesley, worked with associates Hali Knight and Skyla Leavitt on a case study that measured the carbon footprint of Fountain Place Apartments (FPA), a seismic retrofit project by PMA that was completed in November 2022. The project’s objective was to provide seismic and life safety upgrades to this 100-year-old building in an effort to extend its service life at least 50 years. For more background on Fountain Place Apartments, see our “History of Fountain Place Apartments, Formerly Wheeldon Annex”

It was hypothesized prior to the case study that the rehabilitation of FPA had resulted in less embodied carbon than a new building of the same size, based on the accepted view among many in the AEC industry. The case study sought to quantify this hypothesis, and to measure FPA’s finalized carbon footprint.

The building’s carbon footprint was analyzed using the Carbon Avoided: Retrofit Estimator (CARE) Tool ([CARE Tool | Carbon Avoided: Retrofit Estimator]). The CARE Tool not only measures a rehabilitated building’s carbon footprint—it also shows how much carbon was saved by rehabilitating instead of demolishing and building a comparable new building.

Initial Results

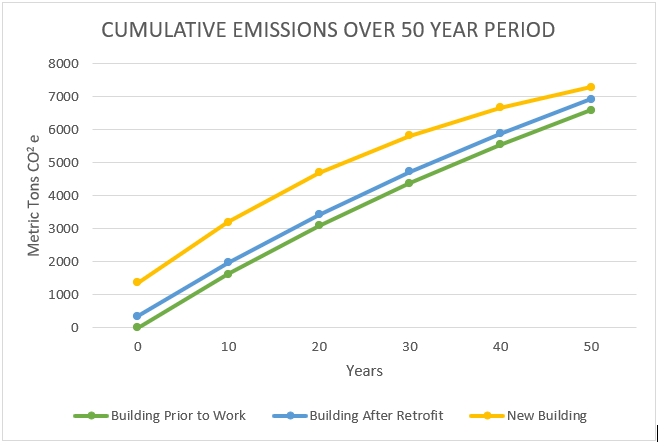

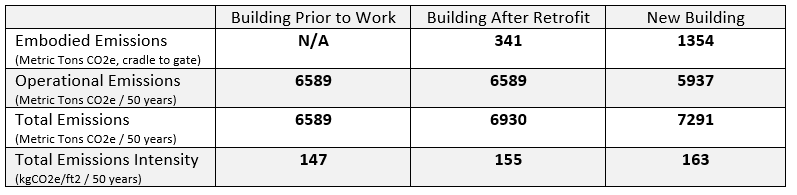

FPA’s project data, as processed by the CARE Tool, showed that the retrofit of the existing Fountain Place Apartment building resulted in significantly less embodied carbon than the construction of a hypothetical new building. The main takeaway from these results is that the retrofit of FPA, despite producing more operational emissions than a new building, had a decreased carbon footprint over a span of 50 years due to a lower amount of embodied carbon. Final numbers calculated by the CARE Tool are found in the table below:

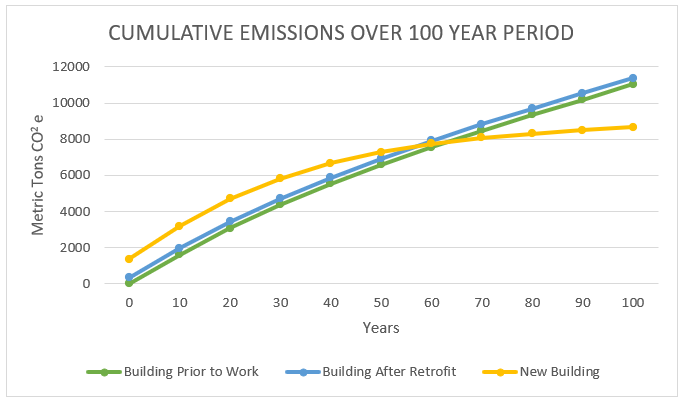

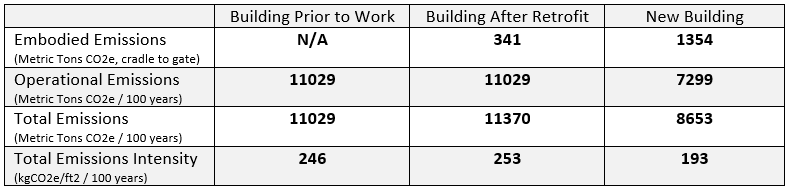

An iterative focus of the case study’s analysis was a 100-year time frame to evaluate if, and when, the carbon footprint of the new building would fall below that of the existing renovation. In 100 years, a new building would likely have had a renovation or even been rebuilt, which would result in alterations to the embodied carbon and operational emissions of the case study’s scenario. The CARE Tool does not calculate for additional embodied carbon stemming from renovations to the new construction over time; this would need to be accounted for in an additional analysis using the tool.

While a hypothetical new building with new electrical and high-performance mechanical systems resulted in lower operational emissions as compared to the retrofit of FPA, the data shows that it would take approximately 70 years for the reduced carbon output from operational emissions to overcome the embodied carbon of a new building’s construction.

Results from analyzing FPA’s project data with the CARE Tool show that the rehabilitation of FPA resulted in significantly less embodied carbon than comparable new construction, and that despite having higher operational emissions than a new building, the retrofit had significantly less total emissions intensity for its 50-year extended lifetime than a new building with a 50-year lifespan. Understanding the impact embodied carbon and operational emissions have on a building’s CO2 emissions intensity is imperative for designers moving forward.

PMA’s case study shows, moving towards a net-zero future can be accomplished, in part, by retrofitting existing buildings. If we attempt to achieve carbon neutrality through a focus on new construction, it will take decades to overcome the additional embodied carbon produced as a product of that new construction. This time frame will likely exceed the Paris Agreement’s limit of the earth warming no more than 1.5 degrees Celsius by 2040 and will contribute to that warming. According to Architecture 2030, approximately two-thirds of the global building stock in 2040 will be buildings that exist today—the majority of these building’s embodied carbon is already locked in place, before rehabilitation or retrofit upgrades like the FPA project. Achieving net-zero requires that these existing buildings be upgraded and updated with systems that minimize their operational emissions.

The arguments for new construction usually fall back on the incorporation of new technology which improves the operational performance of a building, limiting emissions and energy usage. However, operational energy is only half of the data that makes up a building’s total carbon footprint; the other half is embodied carbon. While we have reliable data on operational energy that can be quantified using various metrics, less is known about the impacts of embodied carbon. Part of this is because measuring embodied carbon is difficult; it requires tracking carbon emissions related to a building’s construction prior to the completion of that building and is a game of estimation. Subsequently, embodied carbon has only recently been considered when discussing net-zero targets in the building industry. Its inclusion in the discussion, however, is necessary to holistically measure the environmental impacts of construction—specifically when it comes to comparing the rehabilitation of existing buildings to replacing them with new construction.

PMA plans to publish the case study referenced in this blog in the future, and looks forward to compiling and sharing similar research in the future.

Blog post written by PMA Intern Caitlin Beesley, Design associates Skyla Leavitt and Hali Knight.