Are masonry sealers necessary on historic multi-wythe exterior walls? In general, likely not. Traditional exterior mass unit masonry walls, 3 to 4 wythes thick, leak. But rarely does the amount of water intrusion cause damage to the masonry, the masonry ties, or the interior finishes. Why wouldn’t a sealer be effective for these older walls?

Are masonry sealers necessary on historic multi-wythe exterior walls? In general, likely not. Traditional exterior mass unit masonry walls, 3 to 4 wythes thick, leak. But rarely does the amount of water intrusion cause damage to the masonry, the masonry ties, or the interior finishes. Why wouldn’t a sealer be effective for these older walls?

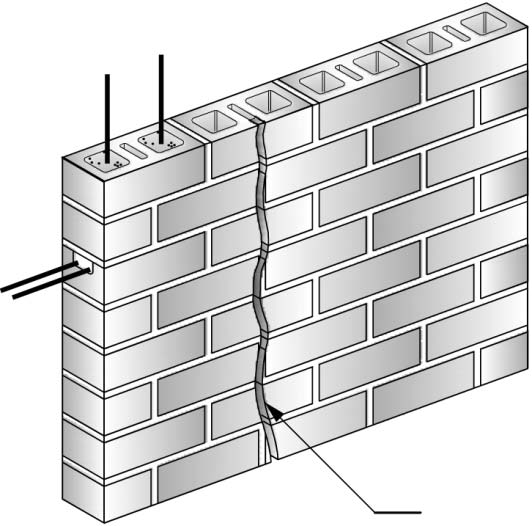

Traditional means and methods of construction multi-wythe walls consist of course work bonded and tied together with header courses, row-lock courses, hidden headers, and set in full beds and back beds of mortar. There is no direct pathway for water intrusion following the mortar beds. And most sealers do not bridge bond line cracks between the masonry unit and mortar bed.

The porosity and absorption rates of older masonry are often exaggerated because of the brick appearance. Many older masonry units show the results of imperfect firing techniques. It is not unusual to see older masonry with vertical and horizontal cracks due to low firing temperatures or impurities in the original clay mix. The surface cracks may lead to higher rates of absorption around the crack but rarely increase the overall absorption or alter the overall characteristics of the masonry. Masonry sealers will not bridge these firing cracks.

The porosity and absorption rates of older masonry are often exaggerated because of the brick appearance. Many older masonry units show the results of imperfect firing techniques. It is not unusual to see older masonry with vertical and horizontal cracks due to low firing temperatures or impurities in the original clay mix. The surface cracks may lead to higher rates of absorption around the crack but rarely increase the overall absorption or alter the overall characteristics of the masonry. Masonry sealers will not bridge these firing cracks.

If older walls exhibit a level of moisture intrusion, the drying dynamics have traditionally been from warm interior side and evaporation towards the exterior. Interior insulation techniques will result in a colder exterior wall that will stay wetter longer. Masonry sealers can impede the natural drying process and movement of water towards the exterior. Vapor permeable “breathable” sealers limit the outward movement of water by natural capillary action impeding the drying dynamics. The major concern with applying sealers to masonry is related to drying.

The Brick Industry Association, Technical Note No. 6A states: “Application of a water repellent coating is not necessary to achieve water resistance in brickwork subjected to normal exposures where proper material selection, detailing, construction and maintenance have been executed.” BIA goes further: “Application is not recommended on newly constructed brick veneer or cavity walls…” There is little to no research showing the effectiveness of sealers on reducing water intrusion in masonry walls. Sealers primarily reduce the initial rate of absorption at the brick surface. Sealers also cannot change water intrusion due to poor construction techniques. Wind driven rain is rarely impeded by sealer applications. “the use of water-repellent coatings to eliminate water penetration in a wall with existing defects can be futile.”

To control water intrusion and to increase performance of a masonry wall, it is much more effective to maintain mortar joints through re-pointing process, assure that mortar joints have no voids, replace brick with spalled faces, replace brick that are cracked the full depth, and repair bond line failures. The use of masonry sealers should be based on known research and field tested success and not chosen as a means to remedy poor construction methods.

To control water intrusion and to increase performance of a masonry wall, it is much more effective to maintain mortar joints through re-pointing process, assure that mortar joints have no voids, replace brick with spalled faces, replace brick that are cracked the full depth, and repair bond line failures. The use of masonry sealers should be based on known research and field tested success and not chosen as a means to remedy poor construction methods.

Written by Peter Meijer AIA, NCARB Principal

When severe deterioration of masonry walls is not a prevalent condition, what other non-visual processes are employed to determine the cause of deterioration? Two common techniques, well known to historic preservation professionals, are non-destructive testing (NDT) and material testing in the laboratory. NDE methods include RILEM tube water absorption tests, metal detector scanning, video scopes, infra-red photography, ultra sound testing, ground penetrating radar, and in some cases, x-ray diffraction. Common laboratory testing include petrographic examination, electron microscopy, and Fourier Transform Infrared (FTIR) methods.

When severe deterioration of masonry walls is not a prevalent condition, what other non-visual processes are employed to determine the cause of deterioration? Two common techniques, well known to historic preservation professionals, are non-destructive testing (NDT) and material testing in the laboratory. NDE methods include RILEM tube water absorption tests, metal detector scanning, video scopes, infra-red photography, ultra sound testing, ground penetrating radar, and in some cases, x-ray diffraction. Common laboratory testing include petrographic examination, electron microscopy, and Fourier Transform Infrared (FTIR) methods.  FTIR, when combined with the diagnostic RILEM tube field test, in particular is an effective evaluation to determine if masonry sealers have been applied to a wall surface impeding the capillary evaporation of trapped water. RILEM tests also provide an observation of a masonry wall’s initial rate of absorption under wind driven rain circumstances. Petrographic analysis of both masonry and mortars determines the material composition and will identify harmful natural elements and harmful additive elements like salts.

FTIR, when combined with the diagnostic RILEM tube field test, in particular is an effective evaluation to determine if masonry sealers have been applied to a wall surface impeding the capillary evaporation of trapped water. RILEM tests also provide an observation of a masonry wall’s initial rate of absorption under wind driven rain circumstances. Petrographic analysis of both masonry and mortars determines the material composition and will identify harmful natural elements and harmful additive elements like salts. A common misconception in the northwest is that surface spalls are a result of freeze thaw cycles. Freeze thaw susceptibility can only be determined through laboratory testing. Visual observations are insufficient to conclude masonry spalls resulted from freeze thaw forces. Since freeze thaw tests are graded either pass or fail, further tests methods are typically required for additional diagnostic evaluation. More likely sources of surface spalls are hard Portland cement mortars which exceed the strength of the masonry, salts introduced into the masonry through incorrect material selection, or surface sealers impeding the evaporation of water and thus creating a saturated sub surface layer which will freeze. (It is important to distinguish that the masonry unit may not be susceptible to freeze thaw but rather the sealer creates a dam like effect inducing a layer of water subject to freezing)

A common misconception in the northwest is that surface spalls are a result of freeze thaw cycles. Freeze thaw susceptibility can only be determined through laboratory testing. Visual observations are insufficient to conclude masonry spalls resulted from freeze thaw forces. Since freeze thaw tests are graded either pass or fail, further tests methods are typically required for additional diagnostic evaluation. More likely sources of surface spalls are hard Portland cement mortars which exceed the strength of the masonry, salts introduced into the masonry through incorrect material selection, or surface sealers impeding the evaporation of water and thus creating a saturated sub surface layer which will freeze. (It is important to distinguish that the masonry unit may not be susceptible to freeze thaw but rather the sealer creates a dam like effect inducing a layer of water subject to freezing) By combining visual observations with NDE and lab testing, most surface masonry deterioration can be determined and thereby implement proper repair, maintenance, and protection methods.

By combining visual observations with NDE and lab testing, most surface masonry deterioration can be determined and thereby implement proper repair, maintenance, and protection methods.

These studies combined with documented field assessments and field evidence of older structures surviving earthquakes and repeated ground motion disturbances over several hundred years are available in numerous communities and offer case study structures for further research. The numbers of university engineering departments with “shake tables” (e.g. Portland State University) create opportunities for joint partnership with private sector consultants, public agencies, and professional organizations to assess and analyze the unique aspects of archaic building materials and methodologies for seismic response. The collaboration between university and private cooperation for seismic research has the potential to develop a wealth of practical and applicable information. The current collaborative efforts involving energy consumption offer the model from which to base seismic research.

These studies combined with documented field assessments and field evidence of older structures surviving earthquakes and repeated ground motion disturbances over several hundred years are available in numerous communities and offer case study structures for further research. The numbers of university engineering departments with “shake tables” (e.g. Portland State University) create opportunities for joint partnership with private sector consultants, public agencies, and professional organizations to assess and analyze the unique aspects of archaic building materials and methodologies for seismic response. The collaboration between university and private cooperation for seismic research has the potential to develop a wealth of practical and applicable information. The current collaborative efforts involving energy consumption offer the model from which to base seismic research.