Window alterations for original single pane glass or new insulated glazing units with new interior storm windows, are growing requests from building owners of historic commercial properties. Two items we recommend to consider regarding these types of alterations: the potential for condensation as a result of the alterations, and the required review processes that may be triggered by exterior alterations to the historic building. In addition, installing a mock-up of proposed window alterations provides the opportunity to accurately measure and document existing and proposed conditions, and review the location of sealant joints and proposed glass types in order to accurately simulate the risk of condensation.

CONDENSATION ANALYSIS

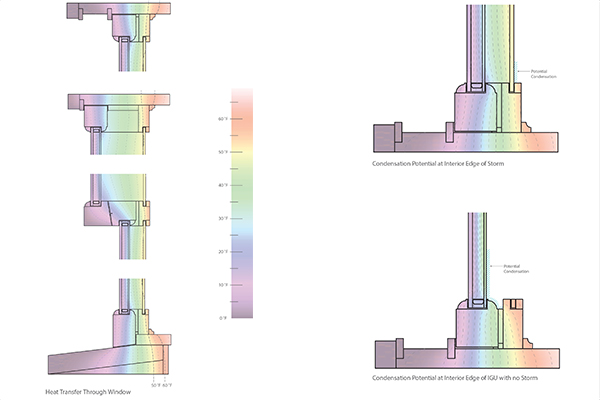

Installation of new storm windows typically reduces the potential for condensation at the interior face of the glass as the surface is kept warmer. However, interior storms can lead to condensation within the interstitial space between the existing window and the new storm window. The condensation is a result of the warm humid air inside the building leaking into the colder interstitial space. As air leaks into the interstitial space, it cools and it can condense on the interior surface of the exterior glazing unit. Moisture/condensation within the interstitial space can cause deterioration of the wood surfaces and obscure views to the exterior.

For this type of condensation analysis, PMA uses THERM, a tool for modeling 2-dimensional heat transfer and WINDOW, a tool for calculating window performance to analyze the windows. The purpose is to understand how the addition of storm windows will impact heat transfer and window performance in order to gauge the potential for condensation. The focus of this type of simulation is determining if the temperature of the air within the interstitial space would reach its dewpoint – indicating water would condense. Following the analysis results, PMA provides recommendations for mitigating and minimizing condensation based on the condensation simulations.

LIMITATIONS

It should be noted that no single tool exists for modeling all of the variables associated with moisture and heat transfer through windows. Hygrothermal analysis (transfer of heat and moisture), is typically limited to 1-dimensional simulation which is inadequate for the complexities of a window which has wood, air, glass, sealant, etc. The 2-dimensional software that has been verified is not currently capable of simulating the complexities associated with heat transfer/soar heat gain through glass surfaces and air. The software we use for window analysis studies is designed to provide the following information:

U-Values

Solar Heat Gain Coefficient (SHGC)

Condensation Resistance Index

Surface Temperature Map of the Entire Window

2-Dimensional Heat Transfer

Additionally, the potential for condensation is directly related to air temperature and relative humidity. Depending on the use of the commercial building, the interior air temperature and relative humidity are expected to vary greatly. The simulations performed as part of this study cannot account for all of the potential temperature/relative humidity variations that may occur. The results may vary depending on different interior/exterior conditions.

MODEL SET UP

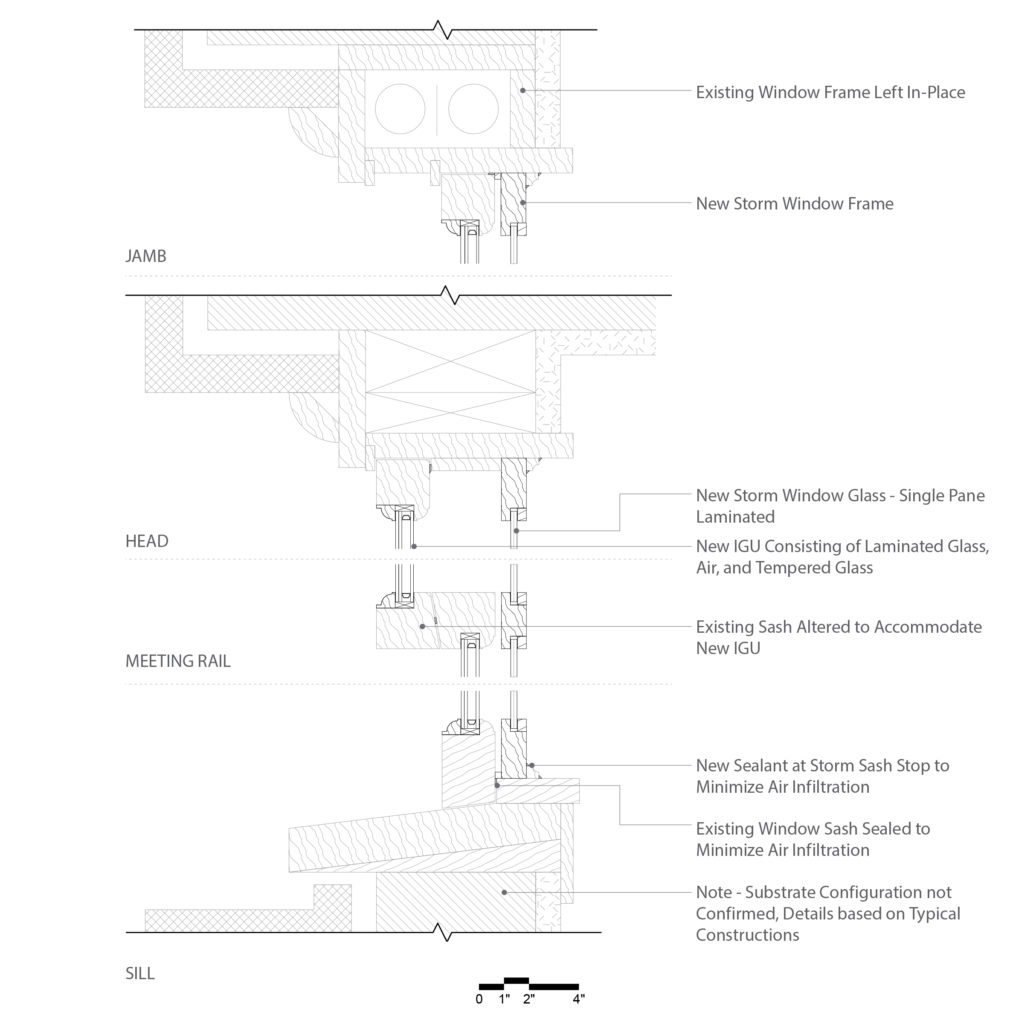

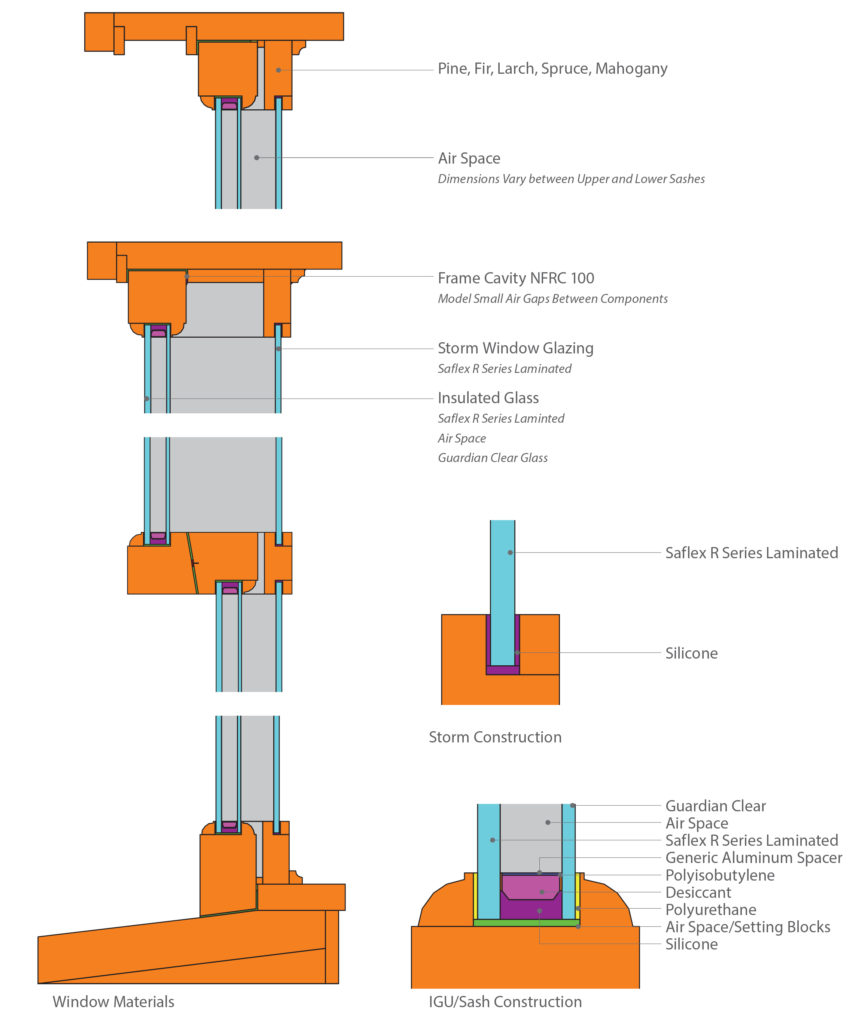

For this type of analysis we develop cross-section drawings for the window head, sill, upper jamb, lower jamb, and meeting rail. The sections are developed based on field measurements (note, sometimes we only have access to interior measurements, making exterior ones approximate). The sections are imported into THERM and modeled to simulate heat flow through the window. We then select glazing systems from the extensive glass library. The systems are selected to match the properties of the proposed materials as closely as possible.

Simulations are set up to run according to the National Fenestration Rating Council (NFRC) standards which specify conditions for simulating the interior and exterior environments. The required exterior temperature is at 0 °F and the interior at 70 °F. These temperatures provide information on more severe conditions than Portland, Oregon, however, they can be used to conservatively predict when condensation is possible. Once the cross sections has been modeled and simulated in THERM, the results are imported into WINDOW to calculate the full window performance, including SHGC, Condensation Resistance Index, U-Value, and temperature Map.

CONCLUSION

While simulations cannot definitively predict the location and quantity of condensation, the results can be interpreted to predict the probability of condensation occurring. Sometimes our analysis shows the possibility that water will condense within the interstitial space, which happens primarily for the following reasons:

The air temperature within the interstitial space is significantly colder than the room air temperature. Any water within air infiltrating into this space may condense under the right conditions. This is exacerbated by the fact that the room temperature and relative humidity may vary greatly and cannot be strictly controlled.

The simulation for predicting condensation on the interior face of the IGU indicated that condensation was possible when the air within the interstitial space matched the properties of the interior air. Under actual conditions, the air within the interstitial space will likely be cooler and more humid than the interior air. The cooler, wetter air will have an even greater potential for condensation.

Condensation within the interstitial space between an existing and storm window is common and several methods are available to reduce the potential for condensation and mitigate any water within the cavity. For clients we provide recommendations with our analysis of window alterations for original single pane glass.

Written by Halla Hoffer, AIA, Assoc. DBIA